Views: 0 Author: Site Editor Publish Time: 2025-07-19 Origin: Site

You might ask how long the process of brewing beer takes. Most home brewing projects take between 2 and a half to 8 weeks. Many people find that 3 to 4 weeks is the ideal timeframe. On brewing day, you’ll spend about 4 to 8 hours actively brewing beer. Fermentation typically lasts 1 to 2 weeks, while conditioning and carbonation add another 1 to 4 weeks. Ales usually finish faster than lagers. The entire brewing beer process depends on several factors:

The beer style and yeast strain used

The size of your brewing equipment

Temperature control in your brewing space

The methods used for carbonation and conditioning

Patience is key when brewing beer at home to achieve great results!

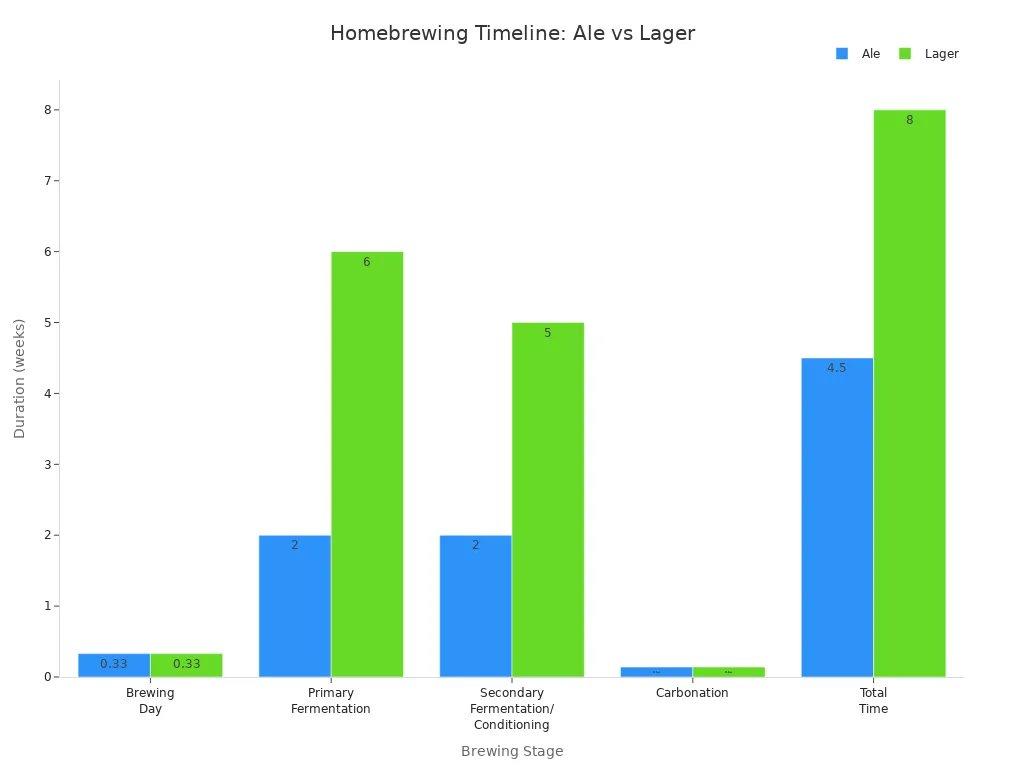

Brewing beer at home takes about 3 to 4 weeks. Lagers need more time and can take up to 8 weeks. This is because lagers need longer fermentation and conditioning.

Ales are ready faster than lagers. They use yeast that works in warm temperatures. This makes ales a good choice if you want beer sooner.

Using extract brewing saves time on brew day. It is faster than all-grain brewing. This makes it easier for people who are new to brewing.

You can make brewing faster by getting your equipment ready early. You can also do other tasks while you wait. Using fast-fermenting yeast like kveik helps too.

Waiting during fermentation and conditioning is important. It gives you better flavor and safer, tastier beer.

When you start brewing beer at home, you might wonder how long each step takes. The brewing process has a few main stages: brewing day, fermentation, conditioning, and carbonation. Each stage has its own timeline, and the total brewing time depends on the style of beer you choose and the method you use.

Here’s a quick look at the typical timeline for brewing beer:

| Stage | Ale Duration | Lager Duration | Notes |

|---|---|---|---|

| Brewing Day | ~8 hours | ~8 hours | Both ales and lagers take about the same time on brew day |

| Primary Fermentation | ~2 weeks | 4-8 weeks | Lagers need more time because of cooler temperatures |

| Conditioning/Lagering | 1-3 weeks | 2+ weeks (3-8 weeks common) | Lagers mature longer for smooth flavors |

| Carbonation | 1-2 days (keg) or 2 weeks (bottle) | 1-2 days (keg) or 2 weeks (bottle) | Carbonation time is similar for both |

| Total Time | 3-6 weeks | 6-10+ weeks | Lagers take longer overall |

You can see that ales usually finish faster than lagers. If you want to enjoy your beer sooner, ales are a great choice. Lagers need more patience, but the clean, crisp taste is worth the wait.

If you use extract brewing, you can save even more time. Extract brewing skips the mashing step, so you spend less time on brew day. Here’s a quick comparison:

| Brewing Step | Extract Brewing Time | All-Grain Brewing Time |

|---|---|---|

| Heat Water | ~30 minutes | ~20 minutes |

| Mash (or steep grains) | ~15 minutes | ~60 minutes |

| Lautering / Sparging | N/A | ~30 minutes |

| Boil | ~60 minutes | ~60 minutes |

| Additional Extract Dissolving | ~5 minutes | N/A |

| Total Estimated Time | ~2 hours | ~3 hours |

So, if you want a faster brewing process, extract brewing is the way to go. All-grain brewing gives you more control over flavor, but it takes longer.

Let’s break down the brewing process into simple steps. Each stage has its own job and timeline. Here’s what you can expect:

Brewing Day

You’ll spend most of your hands-on time here. For extract brewing, you can finish in about 2 hours. All-grain brewing takes closer to 4 hours or more because you need to mash and sparge the grains.

Primary Fermentation

After you pitch the yeast, fermentation starts within 12-24 hours. For ales, this stage usually lasts about 1-2 weeks. Lagers need 4-8 weeks because they ferment at cooler temperatures.

Conditioning/Lagering

Once fermentation slows down, you move the beer to a new container or leave it in the same one to condition. Ales need 1-3 weeks to mature. Lagers go through a special cold aging called lagering, which can last 3-8 weeks or even longer for strong beers.

Carbonation

You can carbonate your beer in bottles or a keg. Bottles usually take 2 weeks to carbonate. Kegs can be ready in just a couple of days if you force carbonate.

Here’s a handy table to help you see the differences for some popular beer styles:

| Beer Style | Fermentation Temp | Active Fermentation | Conditioning Notes |

|---|---|---|---|

| Ales | 62-75 °F | 4-8 days | Shorter conditioning keeps hop aromas fresh |

| Lagers | 46-58 °F | Longer than ales | Extended cold conditioning for smooth, clean flavors |

| Wheat/Belgian Beers | 62-85 °F | Similar to ales | Often crash chilled; less focus on clarity |

| Kveik Yeasts | 86-104 °F | As little as 30 min | Super fast fermentation; conditioning is usually shorter |

Tip: If you want to speed up your brewing time, try using kveik yeast. It ferments at higher temperatures and finishes much faster than regular yeast.

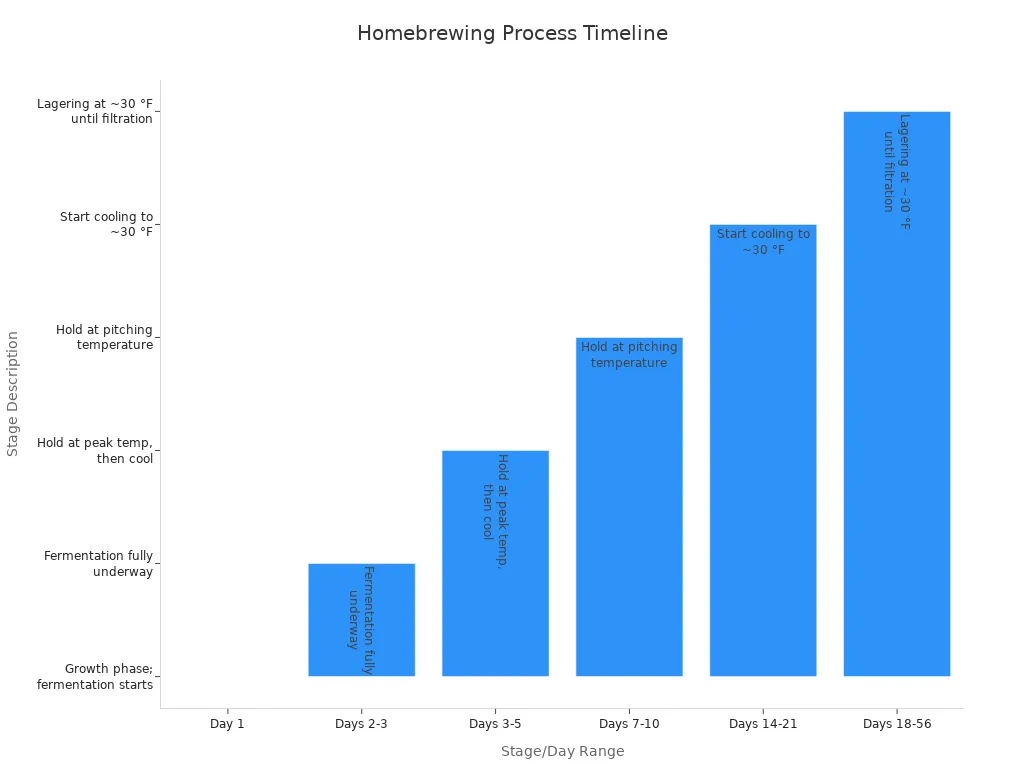

You might also want to see how the brewing process looks over time. Here’s a chart that shows the stages from brewing day to conditioning:

Day 1: Brew your beer and pitch the yeast. Fermentation starts within 12-24 hours.

Days 2-3: Fermentation is in full swing.

Days 3-5: Yeast works hard; you may see bubbling and foam.

Days 7-10: For ales, fermentation slows down. You can start checking if it’s done.

Days 14-21: For lagers, you may start cooling for lagering.

Days 18-56: Lagers go through cold aging (lagering) for several weeks.

After Conditioning: Bottle or keg your beer and let it carbonate.

Note: Some beers, like strong stouts or lagers, need extra time to mellow and develop their best flavors. Patience pays off!

If you want to learn more about brewing beer and improve your process, check out books like How to Brew by John Palmer or join forums like Homebrew Talk. Keeping notes and practicing will help you get better with each batch.

When you start your brewing day, you’ll notice a big difference between extract and all-grain methods. If you use an extract kit, you can finish a batch in under 2 hours. Many home brewers say extract brewing usually takes about 2 to 3 hours from start to finish. Some even finish in just 3 hours, including cleanup.

All-grain brewing takes more time. Most people spend about 4.5 to 5 hours on an all-grain batch, depending on how much they prepare ahead of time. Some experienced brewers can cut this down to under 3 hours by multitasking, but that takes practice. The extra time comes from the mashing and sparging steps, which you skip with extract brewing. If you want to save time, extract brewing is the way to go, especially if you’re new to using a beer brewing kit.

Tip: If you want to try homemade beer but don’t have a whole day, start with an extract beer brewing kit. You’ll get great results with less effort!

On brewing day, you’ll follow a series of steps to turn your ingredients into tasty beer. Here’s a look at the typical hands-on time for each part of the process:

| Brewing Step | Typical Hands-on Time / Notes |

|---|---|

| Milling Grain | About 2-3 minutes of active work |

| Mashing | 90 minutes total; mostly waiting, but setup takes effort |

| Sparging | 60-90 minutes; you’ll need to watch and adjust valves |

| Heating to Boil | 30-45 minutes; keep an eye on the pot |

| Boiling | 90 minutes; stay close to prevent boil-overs |

If you use an extract kit, you can skip milling, mashing, and sparging. That means less time standing over your pot and more time enjoying the process. With all-grain brewing, you’ll spend more time hands-on, but you get more control over your homemade beer. No matter which method you choose, home brewing gives you a chance to learn and have fun.

You might wonder how long does beer take to ferment. The answer depends on the type of beer you want to make. Ales and lagers use different yeast and temperatures, so their timelines are not the same.

Ales use a yeast called Saccharomyces cerevisiae. This yeast works best at warmer temperatures, usually between 60°F and 80°F. Because of this, ales ferment quickly. Most ales finish in about 1 to 2 weeks. You can often taste your ale sooner, which is great if you want fast results.

Lagers use a different yeast called Saccharomyces pastorianus. This yeast likes cooler temperatures, usually between 46°F and 58°F. Cooler temperatures slow down the yeast, so lagers take longer to ferment. You will need to wait 4 to 8 weeks for most lagers. Some traditional lagers, like Pilsners or bocks, need even more time. Lagers also go through a cold conditioning phase called lagering. This step can last from four to ten weeks. It helps the beer become clear and smooth.

Here’s a quick table to compare the fermentation duration for ales and lagers:

| Beer Type | Yeast Used | Fermentation Temp | Primary Fermentation | Cold Conditioning (Lagering) | Total Fermentation Time |

|---|---|---|---|---|---|

| Ale | S. cerevisiae | 60-80°F | 1-2 weeks | 1-3 weeks (optional) | 1-4 weeks |

| Lager | S. pastorianus | 46-58°F | 2-4 weeks | 4-10 weeks | 6-14 weeks |

Tip: If you want to drink your beer sooner, try brewing an ale. If you have patience and want a crisp, clean taste, go for a lager.

Many things can change the beer fermentation time. Here are some factors that affect how long your beer takes to ferment:

The yeast species and strain you choose

The temperature in your fermenting space

How much yeast you add to your wort

The style of beer you brew

The alcohol content and water quality

Some specialty beers use mixed or wild yeast, which can make the time to ferment even longer or less predictable. Breweries often pick yeast strains that match their beer style, which also changes the total fermentation time.

You might feel excited to taste your beer, but you need to make sure fermentation is really finished. How can you tell? There are a few signs you can look for.

The best way to know if your beer is done fermenting is to check the specific gravity. You use a tool called a hydrometer or refractometer. Take a reading, then take another one after two or three days. If the numbers stay the same, fermentation is complete. Airlock bubbles can fool you, so always trust your gravity readings.

You can also look for these signs:

The krausen (the foamy layer on top) changes color and starts to fall

Yeast settles at the bottom of the fermenter

The beer starts to look clearer

Bubbling in the airlock slows down or stops

Most ales finish fermenting in 5 to 7 days if you keep the temperature steady, around 68-72°F. Lagers take longer, so you need to wait several weeks before checking. If your gravity readings are not stable, you can gently warm the beer to help the yeast finish its job.

Note: Always use a hydrometer or refractometer to check if your beer is ready. This method is more reliable than watching bubbles.

Fermenting beer takes patience, but it is worth it. When you wait for the right signs, you get better flavor and a safer, tastier drink.

When you finish fermenting your beer, you still need to carbonate it. You can choose between bottle conditioning and keg conditioning. Each method has its own timeline and steps.

Bottle conditioning usually takes about two weeks at room temperature. You add priming sugar to each bottle, and the yeast creates natural carbonation.

Keg conditioning with yeast and sugar works best at room temperature. If you keep the keg cold, the yeast slows down or stops, so carbonation takes much longer or may not happen at all.

Some brewers leave their kegs at room temperature for about two weeks before chilling them. This helps the beer carbonate naturally.

Forced carbonation in kegs uses CO2 tanks. This method is much faster. You can have carbonated beer in just a few days or even hours, depending on the pressure and method you use.

Tip: If you want your beer ready fast, forced carbonation in a keg is the quickest way. Bottle conditioning takes longer but gives you classic, natural bubbles.

Here’s a quick comparison:

| Method | Typical Timeframe | Notes |

|---|---|---|

| Bottle Conditioning | 2 weeks at room temp | Natural carbonation, more flavor maturity |

| Keg Conditioning | 2+ weeks at room temp | Needs warmth for yeast to work |

| Forced Keg Carbonation | 1-7 days (or less) | Uses CO2, much faster |

You might wonder when your beer is finally ready to drink beer. Several things affect this moment:

Conditioning temperature should stay between 68-80°F for best yeast activity.

Most beers need 7-14 days for carbonation. Some styles need up to 4 weeks for full flavor.

Warmer storage speeds up carbonation. Cold storage slows it down or stops it.

Healthy yeast and the right amount of priming sugar help your beer carbonate well.

Corn sugar is common for predictable results in 2-4 weeks. Honey or other sugars can take longer.

The age of your beer at bottling matters. Young beer may need more time to mellow.

Beer style changes the timeline. IPAs can be ready in 3 weeks. Stronger beers, like barley wines, may need months.

Tasting your beer after two weeks helps you decide if it is ready.

Note: Always check your beer’s carbonation and taste before sharing it. Sometimes, a little more time makes a big difference.

When you see steady bubbles and the flavor tastes smooth, you know your beer is ready to drink beer. Enjoy the moment—you made it yourself!

You might notice that the type of beer you brew and the yeast you choose can change your brewing time a lot. Some yeast strains work fast, while others take their time. Here’s how different styles and yeast strains affect your brewing process:

Ale yeast likes warmer temperatures and finishes fermentation quickly, sometimes in just 2–4 days.

Lager yeast works at cooler temperatures and needs more time to finish, often several weeks.

Higher fermentation temperatures make yeast work faster but can change the flavor.

The yeast strain you pick also changes how clear your beer looks and how stable the foam is.

If you adjust the temperature a little, you can help the yeast finish faster, especially with strong beers.

Choosing the right yeast for your beer brewing kit can help you control your brewing time and the final taste.

The equipment you use can make your brewing process faster or slower. Some homebrewers use energy-saving systems that reuse heat and water. This helps you save time and resources. Larger brewing systems let you make more beer at once, but they might take longer to process each batch. Special tools like carbonation stones or kegging systems can help you carbonate your beer faster than traditional bottle conditioning.

If you use a beer brewing kit with modern features, you can often shorten your brewing time. For example, forced carbonation in a keg is much quicker than waiting for bottles to carbonate naturally.

Want to make your brew day go faster? Try these tips:

Get all your brewing materials and equipment ready the day before.

Use hot water from your heater to reach the right temperature quickly.

Multitask during waiting times—clean equipment or measure ingredients while you mash or boil.

Use an immersion chiller with a stirring device to cool your wort in under 10 minutes.

Clean up as you go to save time at the end.

Speed up liquid transfers with mesh strainers or ball valves.

Brew larger batches to save time per gallon.

Some brewers use kveik yeast for even faster results. Kveik can ferment at high temperatures and finish in about a week. It also settles quickly, so you can enjoy your beer sooner. Just remember to watch the temperature to keep the flavor right.

Tip: Using a beer brewing kit with kegging and fast yeast can help you enjoy your homemade beer in record time!

You now know that brewing takes time, but each stage matters. Here’s a quick look at expert timelines:

| Stage | Fastest Time | Longest Time | Tip |

|---|---|---|---|

| Ales (fermentation) | 6 days | 2-3 weeks | 3 weeks is a safe rule |

| Bottle Conditioning | 2 weeks | 2 months | Longer aging, better taste |

| Lagers (lagering) | N/A | 8-12 weeks | Needs patience |

Want to avoid delays? Watch out for these common mistakes:

Underpitching yeast or pitching too hot

Poor wort aeration

Not stirring malt extract enough

Patience pays off. Letting your brew condition gives you smoother flavors and better results. As you gain experience, you’ll find ways to save time without rushing. Enjoy the process—there’s nothing like tasting something you made yourself!

You can expect most homebrewed beers to take 3 to 4 weeks. Some styles need only 2½ weeks, while lagers or strong beers may need up to 8 weeks. Patience gives you better flavor!

No, you should not drink it right away. Your beer needs time to carbonate and condition. Wait at least 1 to 2 more weeks after fermentation for the best taste and bubbles.

Try using kveik yeast and force carbonation in a keg. You can have drinkable beer in about a week. Extract kits also save you time on brew day.

Yes! Warmer temperatures help yeast work faster. Cooler temperatures slow things down, especially for lagers. Always follow the recommended range for your yeast to get the best results.